Handpan Crafting 101

Steel Selection

The quality of a handpan begins with the quality of the components. In the case of the handpan, that's just steel! Or is it *just* steel?

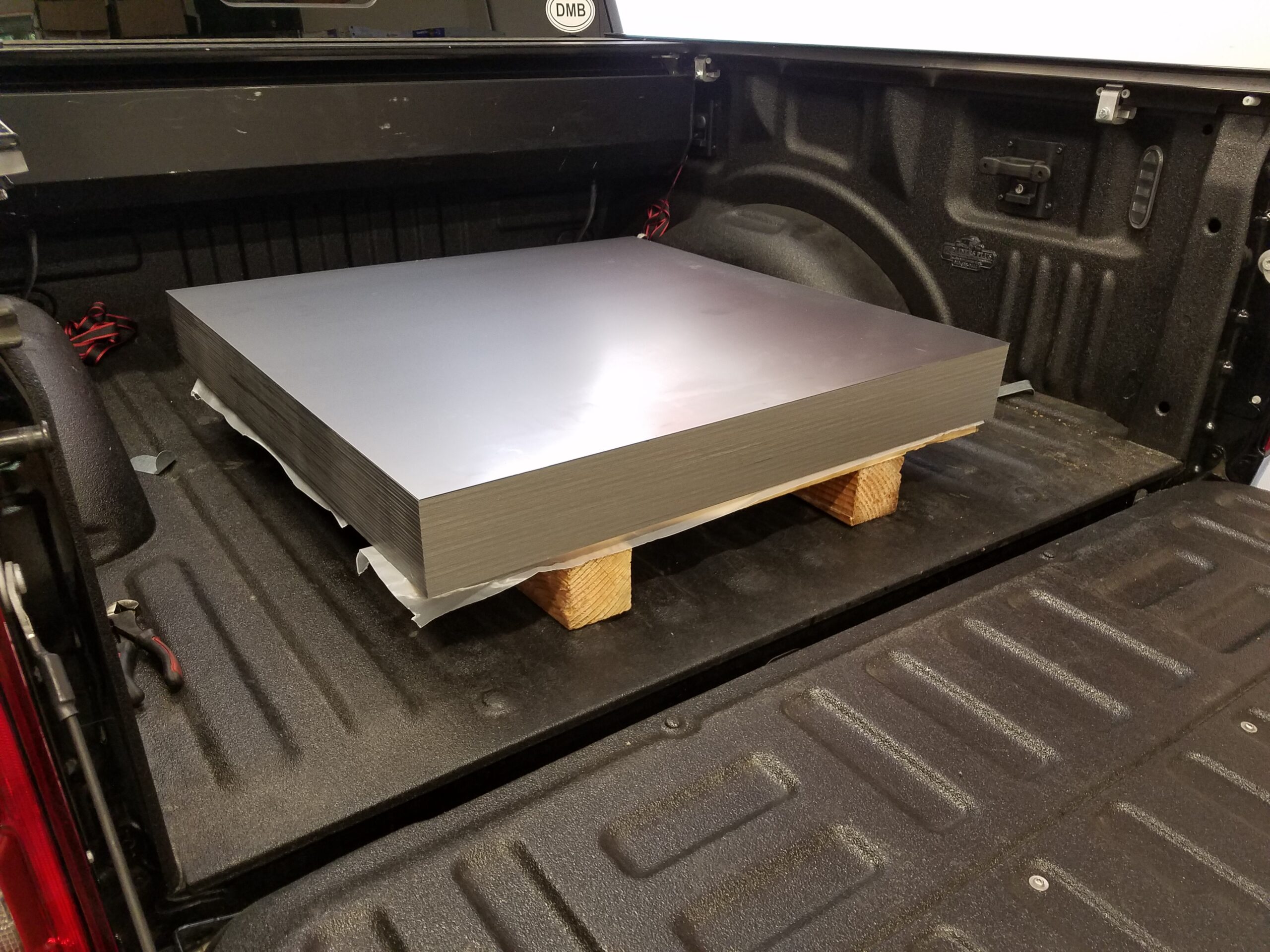

Truth be told, there is a lot of work involved when it comes to steel selection, and it depends on what the handpan crafter's end goal is. If the handpan will be heat-treated and hardened via nitriding, then a low carbon steel is generally used. Common grades of low carbon steel in the United States would be 1004 or 1008. These are relatively low-quality grades, so I take care in working with my suppliers to find a coil of steel that has my preferred chemistry. I do this by requesting the 'certs' (short for certifications). This paperwork will tell me what percentage of each element is in the steel. Carbon is the most important to me, but other elements, such as sulfur, are also seen in these reports. I keep these numbers to myself, as they are quite important for the nitriding process, and can definitely be considered part of the 'secret sauce'. Once I find a batch I like that works well with my nitride process, I order several tons of steel from that batch (usually cut from a large coil).

I’ll cut off the discussion of nitriding for now, as that is a very big topic that deserves its own page (or perhaps a book, haha). I will say, all nitrided handpans are not the same, and can vary wildly from maker to maker.

Stainless Steel

If I will not be nitriding, then I will opt for stainless steel. Certain grades of stainless steel are able to be work hardened very easily, and having a hard steel is very important for quick and consistent tuning down the road. Stainless steel has the added benefit of rust resistance, so handpans made from it will be more tolerable to the elements, such as playing nearing the ocean or in humid environments like the rainforest.

Stainless steel is all the rage nowadays, and for good reason. In addition to the benefits already mentioned above, it is well-known for its easily attainable sustain, allowing for a more meditative playing style.

One downside of stainless steel is that it *does* have more sustain, than say, nitrided handpans. Some handpan players have a more percussive and fast style, such as my friend Adrian Portia. That's not to say stainless is a bad fit for him, but it simply requires a different technique.

There are many grades of stainless steel available. 300 series, 400 series, and more. I have experimented with many of them, and they all seem to have a level of uniqueness amongst them. Most handpan makers, and myself included, tend to favor the grade 430. It doesn't work harden too quickly, but it still provides a good timbre and it is not too difficult to tune for an experienced handpan maker.

I have also tried 300 series stainless steel, and boy was that a workout! Stainless 316 will work harden VERY quickly, and it feels nearly impossible to shape the tone fields. It was an interesting experiment, but the overall timbre was one I did not care for.

Some folks ask me about other metals, such as aluminum or copper. While I have not tried them, I know others who have and had poor results, to the point that the instruments were not even tunable. Those metals are simply too soft for tone generation in a steel instrument like a handpan. Handpan notes are under a compressive stress in order to generate a tone, and soft materials simply do not have the hardness and rigidity to maintain a high level of internal stress. That also is a topic for another time.

That’s all for now, but hopefully this has answered some questions, and perhaps has raised others, when it comes to selecting steel for Iskra handpans.